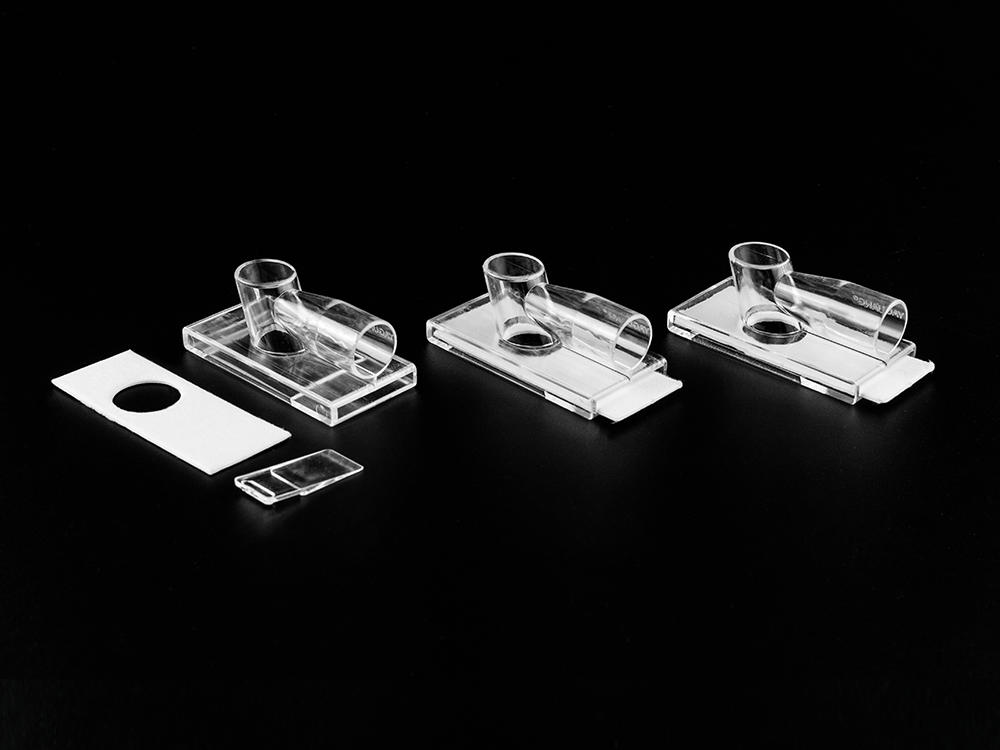

In the field of centrifuges, the sealing clip is one of the key components to ensure the efficient and safe operation of the centrifuge. The L-07 ABS/PP Big Hole Horizontal Type Centrifuge Smear Clips is made of ABS/PP (acrylonitrile-butadiene-styrene/polypropylene), which gives it unique advantages. So why choose these two materials?

ABS material is known for its excellent comprehensive performance. It has good impact strength, heat resistance, low temperature resistance, chemical resistance and electrical properties. It also has the characteristics of easy processing, stable product size and good surface gloss. During the operation of the centrifuge, the sealing clip needs to withstand the pressure and friction generated by high-speed rotation. The high strength and wear resistance of ABS enable the L-07 sealing clip to maintain a stable sealing effect for a long time, ensuring the normal operation of the centrifuge. PP material (polypropylene) also provides important performance support for the L-07 sealing clip. PP material has excellent chemical corrosion resistance, heat resistance, electrical insulation and good processing performance. In centrifuge applications, PP material can resist the erosion of various chemicals, ensuring that the sealing clamp will not be damaged by corrosion. At the same time, its good heat resistance allows the L-07 sealing clamp to maintain stable performance in high temperature environments.

The combination of ABS/PP materials also brings additional advantages. ABS and PP have certain complementarity in physical and chemical properties. Their combination enables the L-07 sealing clamp to maintain high strength and wear resistance while also having good chemical corrosion resistance and heat resistance. This double guarantee enables the L-07 sealing clamp to maintain stable performance in various complex centrifuge working environments.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch عربى

عربى