High-throughput PCR deep well plates are designed to accommodate a large number of samples simultaneously, making them particularly suitable for high-throughput applications in molecular biology and genomics research.

Well capacity: PCR deep well plates come in various formats, such as 96-well, 384-well, or even 1,536-well plates. The choice of plate format depends on the scale of your experiment and the number of samples you need to process. Larger well capacities allow you to process more samples at once, increasing throughput.

Automation compatibility: High-throughput PCR deep well plates are often designed with compatibility for automated liquid handling systems and robotic platforms. Automated pipetting systems can rapidly and accurately distribute reagents and samples across the wells, significantly increasing throughput while minimizing human error.

Multi-channel pipetting: Multi-channel pipettes can be used with PCR deep well plates to simultaneously dispense or aspirate samples from multiple wells. For example, an 8-channel pipette can process eight samples at once in a 96-well plate, further enhancing throughput.

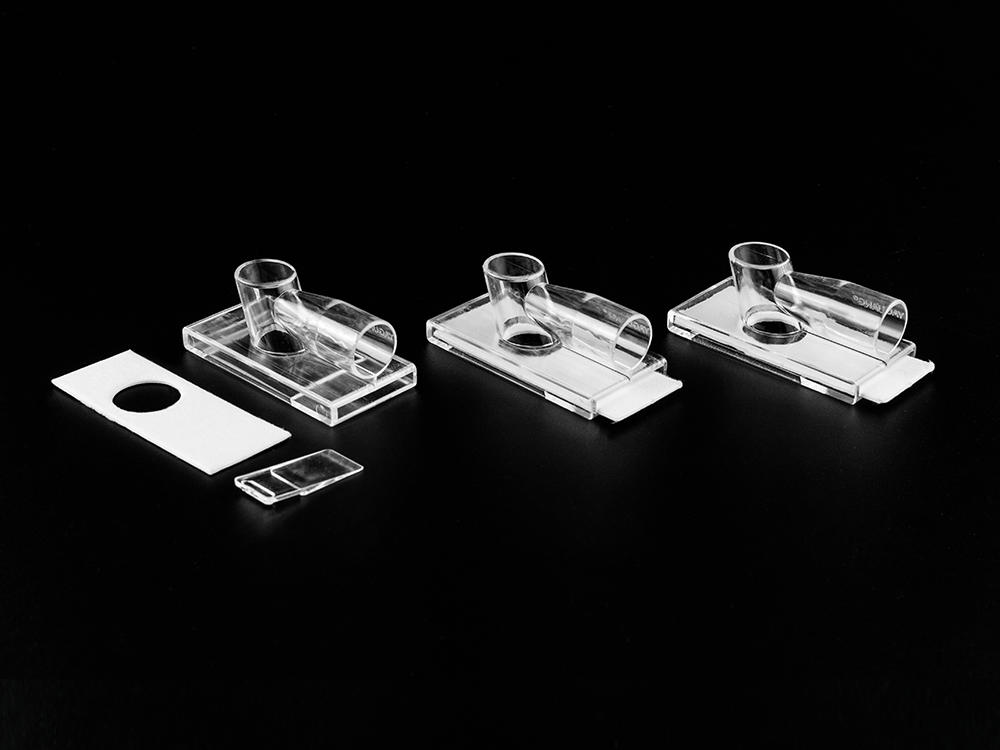

Plate sealing options: To prevent sample evaporation and contamination during thermal cycling, high-throughput PCR deep well plates offer various sealing options. These include adhesive seals, heat seals, or caps with sealing mats. Proper sealing is crucial when processing multiple plates simultaneously.

Plate handling equipment: Specialized equipment, such as plate handlers or stackers, can be used to automate the loading and unloading of PCR deep well plates on thermal cyclers. This reduces the time required for manual plate handling, increasing throughput.

Thermocycler capacity: When performing PCR on a large number of samples, it's essential to have access to a thermal cycler with the capacity to accommodate multiple deep well plates simultaneously. Some thermal cyclers are designed to run several plates at once, further enhancing throughput.

Workflow optimization: Efficient workflow planning and optimization are crucial for achieving high-throughput with PCR deep well plates. This includes designing primer and sample layouts, ensuring proper mixing of reagents, and minimizing any dead times during the process.

Sample tracking and documentation: Implementing a robust sample tracking and documentation system is essential for managing large numbers of samples accurately. Barcode labeling and a well-organized sample tracking database can help ensure data integrity and prevent errors.

Quality control measures: Even in high-throughput applications, it's essential to include quality control measures, such as controls and replicates, to ensure the reliability of your results.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch عربى

عربى