Industrial uses of centrifuge tubes play a crucial role in various purification and separation processes across a spectrum of industries. These tubes, typically made from durable materials such as plastic or glass, are engineered to withstand high-speed centrifugation, allowing for efficient separation of substances based on their density, size, or other physical properties.

One of the primary applications of centrifuge tubes in industrial settings is in the field of biotechnology and pharmaceuticals. Here, centrifugation is employed for the separation of biomolecules such as proteins, DNA, and RNA. Centrifuge tubes are utilized to isolate these valuable compounds from complex mixtures such as cell lysates or culture supernatants. This purification step is essential in downstream processes like drug development, where the purity of biomolecules greatly impacts the efficacy and safety of pharmaceutical products.

In the chemical industry, centrifuge tubes are utilized for the separation and purification of various compounds and mixtures. For instance, in the production of fine chemicals or specialty chemicals, centrifugation is often used to separate reaction products, remove impurities, or concentrate solutions. Centrifuge tubes enable precise control over these processes, facilitating the production of high-quality chemical products with consistent purity levels.

Centrifuge tubes find extensive use in the environmental sector for the analysis and treatment of wastewater, sludge, and contaminated soil. In wastewater treatment plants, centrifugation is employed to separate suspended solids from liquid effluents, facilitating the removal of pollutants and the purification of water before discharge. Similarly, in soil remediation projects, centrifuge tubes are utilized to isolate and concentrate contaminants, allowing for their proper disposal or remediation.

The food and beverage industry also relies on centrifuge tubes for various purification and separation applications. From clarifying fruit juices and vegetable oils to separating solids from liquid food products, centrifugation helps enhance the quality, shelf-life, and safety of consumable goods. Centrifuge tubes enable efficient processing of large volumes of food and beverage samples, ensuring compliance with regulatory standards and consumer expectations.

Industrial uses of centrifuge tubes for purification and separation processes are diverse and wide-ranging. Whether in biotechnology, pharmaceuticals, chemicals, environmental science, or food production, these tubes play a vital role in enabling efficient separation of substances, leading to improved product quality, process efficiency, and environmental sustainability. As technology advances and industries evolve, the importance of centrifuge tubes in industrial applications is likely to continue growing, driving innovation and advancements in centrifugation techniques and equipment.

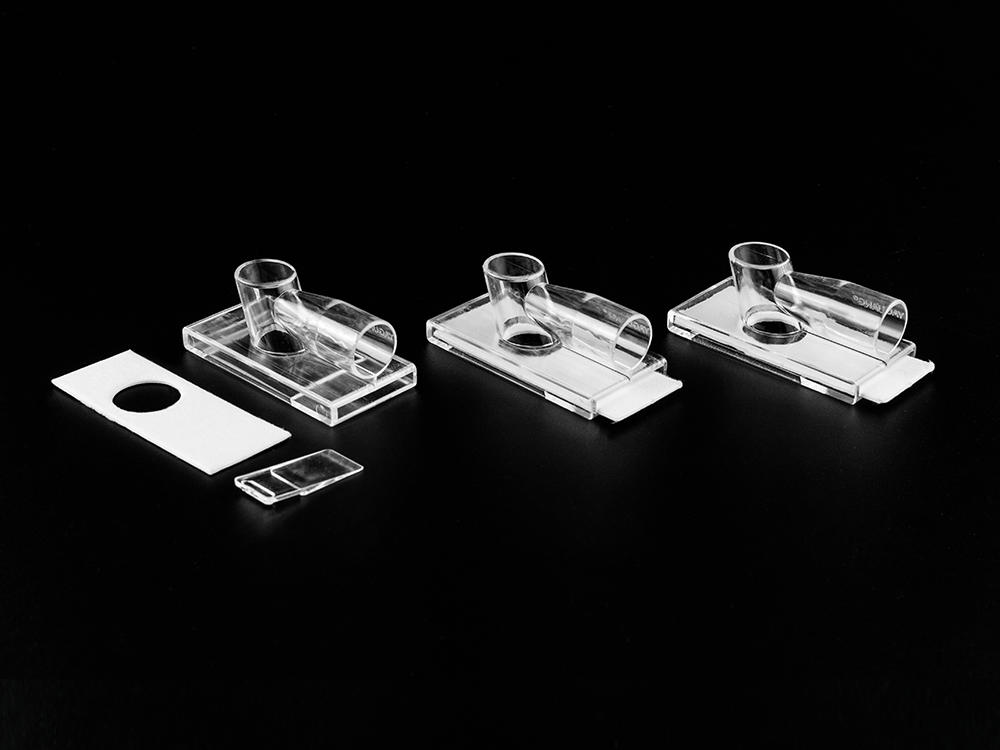

15ml Tapered Bottom Disposable PP Centrifuge Tubes

15ml Tapered Bottom Disposable PP Centrifuge Tubes

1. 15ml Centrifuge tubes,gradation at 15ml;

2. Subuliform bottom and can't be put flat;

3. Cap color can be customizable;

4. Can do logo or printing;

5. There is a white sticker on the body;

6. Made for high quality medical polypropylene;

7. Leakproof

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch عربى

عربى